Wrapping car parts can be challenging and requires attention to detail. When considering what is the hardest part of a car to wrap, it’s important to note that surfaces must be thoroughly cleaned, as dirt prevents the vinyl from adhering properly. Complex curves and intricate shapes on vehicles demand extra care to avoid wrinkles or bubbles. Additionally, factors like heat and sunlight can further complicate the wrapping process. Successfully wrapping a car requires both skill and meticulous preparation.

Material Challenges

Adhesion Issues with Unpainted Plastics

Unpainted plastics can make wrapping with vinyl tricky. These surfaces are not as smooth as painted ones. Their rough texture stops the vinyl from sticking well. Over time, the vinyl might peel or form bubbles. Some plastics, like polypropylene and polyethylene, are harder to wrap. This is because of their chemical makeup. These materials are often used in cars but resist sticking. To help the vinyl stick better, use a primer or special surface treatment.

Problems with Rubber and Flexible Materials

Rubber and flexible parts are tough to wrap with vinyl. These materials don’t hold adhesive well because of their properties. Rubber is made to handle heat and chemicals, which makes wrapping harder. It can also break down from sunlight or ozone, causing wraps to fail. Flexible parts, like seals or trim, can move or stretch. This movement can create wrinkles or tears in the vinyl. To fix these problems, use good-quality vinyl and prepare the surface carefully.

Painted vs. Non-Painted Surfaces

Painted surfaces are easier to wrap than non-painted ones. Paint makes a smooth layer that helps the vinyl stick. Non-painted surfaces are often rough or porous, making wrapping harder. If wrapping non-painted parts, you might need to sand or treat them first. Painted areas also need checking for damage. Peeling or broken paint can ruin the wrap. Always fix any issues before applying the vinyl.

What Is the Hardest Part of a Car to Wrap?

Wrapping Curves and Contours

Curves and shapes on cars are hard to wrap. These spots need vinyl to stretch smoothly without wrinkles or bubbles. Bumpers and fenders have tricky designs needing extra care. Studies show wrapping curves fails more in hot weather. Heat makes vinyl stretch unevenly, causing it not to stick well. To get a smooth look, use heat gently and press evenly. Without good skills, these spots are the hardest to wrap.

Small or Intricate Parts (e.g., Door Handles, Mirrors)

Small parts like door handles and mirrors are tough to wrap. These parts have tight spaces and odd shapes, making vinyl stick unevenly. Wrapping unpainted plastic, like mirrors, can wear out fast. Surveys say door handles are the hardest because of their design. Wrapping these needs patience and skill to cut vinyl just right. Even small errors can cause peeling or rough edges.

Sharp Edges and Multi-Angled Panels

Sharp edges and angled panels are tricky for vinyl wrapping. These spots need the vinyl to bend in many ways, risking tears. Edges of hoods or trunks wear out faster, making wrapping harder. Graphics on these areas must line up perfectly to look good. Using strong vinyl and special tools helps get a neat finish. But these spots often need expert skills, so many ask for professional help.

Environmental and Preparation Factors

Why Cleaning and Prepping the Surface Matters

Getting the surface ready is key for a perfect vinyl wrap. Dirt, grease, or wax can stop the vinyl from sticking well. First, wash the car with mild soap and water to remove grime. Then, dry it fully with a soft, lint-free cloth. For stuck-on dirt, use a clay bar to smooth the surface.

If the paint has scratches or damage, fix them before wrapping. These flaws can make the vinyl bubble or peel later. A clean, smooth surface helps the vinyl stick better and last longer.

How Temperature and Humidity Affect Wrapping

Weather conditions can make wrapping harder. Very hot weather makes vinyl stretch too much. Cold weather makes it stiff and hard to use. The best temperature for wrapping is between 68°F and 77°F.

Humidity also matters. Too much moisture in the air can weaken the vinyl's glue. Always work in a dry, well-ventilated space to avoid problems.

Why Dust and Dirt Can Ruin Wraps

Dust and dirt can mess up a vinyl wrap. Even small bits can cause bumps or wrinkles, making it look bad. Check the workspace for dust and clean it well before starting. Wipe the car with a tack cloth right before applying the vinyl. A clean area helps the wrap look smooth and last longer.

Expertise and Tools Needed

Why Professionals Are Better for Complex Wraps

Wrapping a car takes more than sticking on vinyl. Experts have the skills to handle tricky designs and avoid bubbles or mistakes. They prepare surfaces well so the wrap sticks better and lasts longer. They also know how to use heat carefully to stretch vinyl without ruining it.

Hiring a pro saves time and avoids problems. For example:

- They work faster, so your car is ready sooner.

- They protect both the wrap and your car's paint.

When picking a pro, check their past work and reviews. Look for someone with experience and attention to detail.

Tools That Help with Wrapping

Special tools make wrapping easier and more accurate. Heat guns help stretch vinyl over curves. Squeegees push out air bubbles for a smooth look. Other tools, like knives and edge sealers, make sharp edges and keep wraps lasting longer.

Using these tools well saves time. For example, pros can finish a full wrap in 1 to 2 days. This speed makes customers happy and helps businesses grow.

Mistakes Beginners Often Make

Beginners often skip important steps. Not cleaning the surface or using the wrong tools can ruin the wrap. Wrinkles, bubbles, and peeling edges are common problems. Sharp edges and angled panels are also hard for beginners to wrap neatly.

To avoid these issues, start with small parts to practice. Use good tools and materials. If a part is too hard, ask a pro for help.

Wrapping car parts can be hard for many reasons. Material types, tricky shapes, and weather all play a role. Getting the surface ready and using good tools helps a lot. Experts can handle tough spots and make wraps look perfect.

| Evidence Type | Description |

|---|---|

| Quality of Wrap Shop | Picking a good shop improves how the wrap looks and lasts. |

| Professional Installation | Skilled installers stop problems like bubbles or peeling. |

| Use of Quality Materials | Great shops use trusted brands for wraps that last longer. |

| Installer Experience | Installers with practice do better on hard-to-wrap car parts. |

| Warranty | Good shops give warranties to show they trust their work. |

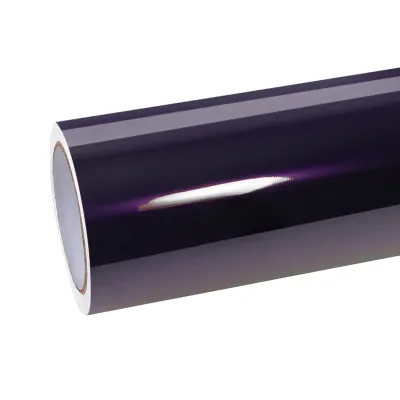

Think about how hard the car parts are to wrap first. For tough spots, hiring a pro saves time and gives better results.The next blog post will be about custom car wraps, pink car wrap and midnight purple wrap.

0 Comments